high-voltage technology

secure connections for future mobilityFor the mobility of the future – safe connections in the high-voltage range of HEVs, BEVs and FCEVs

About ten years ago, we designed the first connection technology for geared motors together with an OEM. This led to the development of the e-traction/power train division for geared motors in the e-mobility sector, which now extends to fully automated production.

Today, our applications in the HEV, BEV, FCEV include:

- power distribution via busbar wiring systems and power distributors,

- connections of plug-in systems to high-voltage cables,

- butt or overlap welded connections from busbars to cables and braids for module connectors of the individual high-voltage storage systems,

- connections in the high-voltage electrical system from the vehicle battery to the inverter or from the inverter to the electric motor up to the phase connection in the CCS,

- connections in the ECUs,

- components,

- traction distributors,

- pyro fuses,

- connection technology in the geared motor (phases and star points) and

- connection to current rings.

safety first

In general, this field involves welding high-voltage connector systems to high-voltage cables (HV cables) with cross-sections of 25 to 120 mm² for cable plug-in systems or busbars. We can also implement traction distribution systems for four-wheel-driven EVs with cable cross-sections of up to 300 mm².

Absolute reproducibility in the connection is of the utmost importance here, as there is a risk of fire in the event of a field failure. For this case, we have developed systems for welding under braze that enable fully automatic production including monitoring.

Our custom STRUNK MES software ensures individual product-related traceability. It provides the required data by networking the systems in individual production steps within automated production in an SQL database. Alternatively, the data records can be uploaded to your specific MES system according to your requirements.

In the field of HEV, BEV and FCEV e-drives, connections can be created for wound stators or hairpin stators. The former are joined using hot crimp technology while hairpin stators are connected by resistance brazing. Both result in reliable, non-ageing material-to-material connections.

High-voltage cable set and module connectors

Cable and non-ferrous metal connections in EVs must be designed to withstand high current loads. Furthermore, the contact resistances at the connections must be kept close to zero. If these requirements are not guaranteed, this results in heating (hot spots), which lead to field failure due to further increasing resistance. We therefore aim to achieve transmission with as little loss as possible. Additionally, the mechanical holding forces are extremely important to avoid high-impedance effects or loosening of the connection even under mechanical and environmental stress. In these cases, our technologies offer you options for achieving secure and demonstrably long-term stable connections even under high loads.

In the field of high-voltage technology, we develop and manufacture solutions for the following areas of application:

- e-traction: everything related to the power train, e. g. welding of phase connections and star points,

- connections to stators using winding and hairpin technology,

- connection technology for rotors,

- connection technology in assembly (phase connection to terminal boards),

- power distribution/busbars/lead frames: HV electrical systems, busbar electrical systems in vehicles,

- HV storage systems: development of new technologies for battery cell connectors (HV cable set),

- HV connection technology from HV cables to HV connectors,

- AC/DC charging systems and

- pyro fuses.

We can also connect components for HV wiring using the methods of overlap or butt welding under braze.

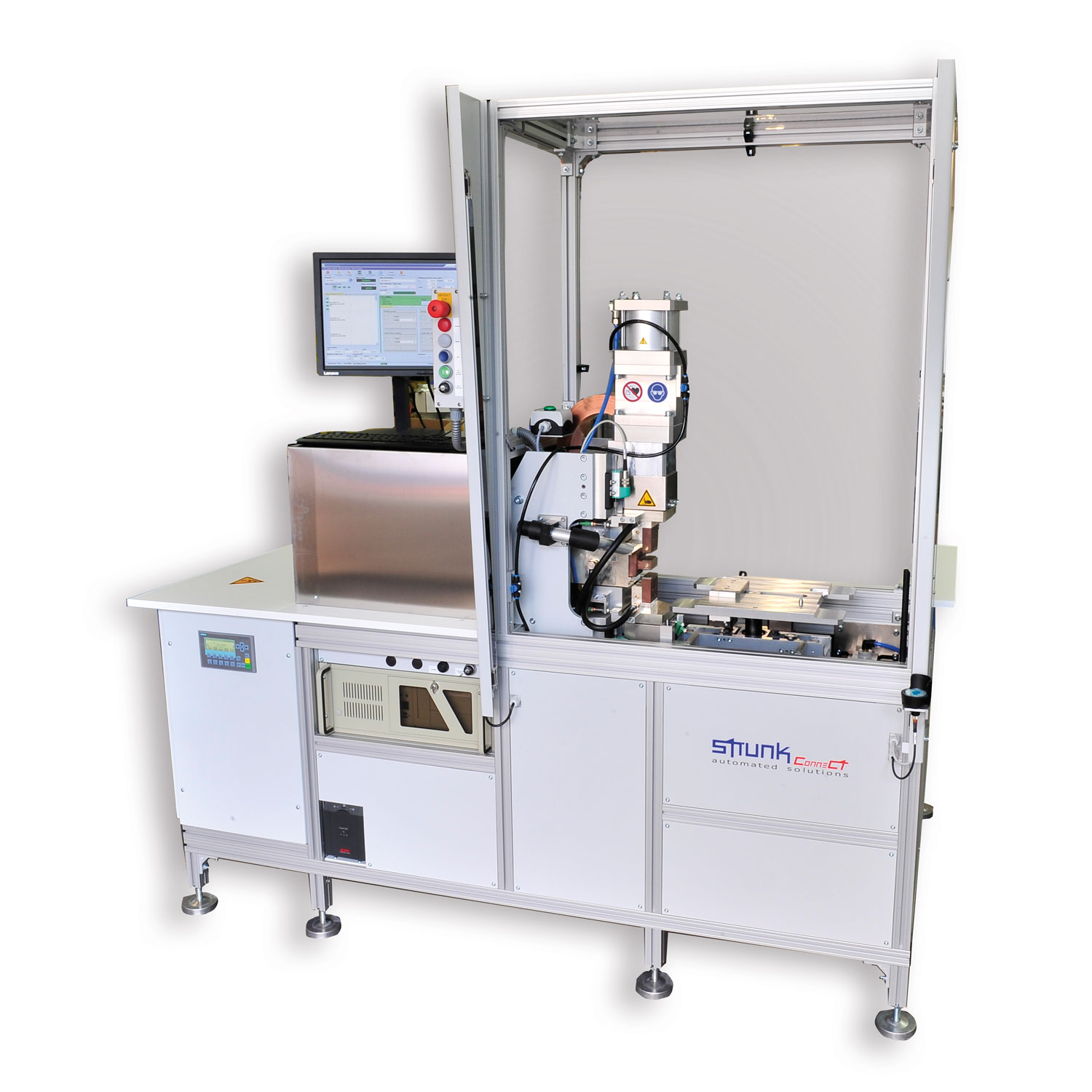

Machines

(customer-specific solutions as an example)

Busbar welding systems for applications under braze

This is a flexible manual welding system for connections under braze in the field of power distribution. It can be used to join busbars to connection elements (HV connectors), HV cables and braids. The narrow design and quick-change tools enable the production of busbars with difficult geometries. Our flexible STRUNK servo braze feeder with integrated monitoring can be connected on the right and left side at various angles. At an angle of 0°, this enables different brazing tape widths to be fed through the welding unit. A conversion kit for compacting cables and braids up to 120 mm² is also available. Full traceability is guaranteed via camera or DMC. Additionally, this welding cell can be connected to STRUNK MES or your specific MES software.

Semi-automatic double-head transfer for HV connectors

This flexible semi-automatic welding cell with transfer is suitable for compacting under braze and welding the compacted cable onto an HV connector. By compacting under braze and automatically transferring the compacted wire, the most precise dimensions and reproducibility are achieved. A changeover to another HV connector can be carried out quickly by simply replacing the welding nest. The gripper systems have NOK cutters and full traceability is guaranteed via camera or DMC. Additionally, this welding cell can be connected to STRUNK MES or your specific MES software. It can be used for cross-sections from 6 to 95 mm².

Welding cell with S-MMD3/150 for connecting HV cables with terminals, busbars and HV connectors

This manual welding cell with automatic STRUNK servo braze feeder is mounted on quick-change couplings. Tools on quick-change plates enable rapid conversion to another application. Full traceability is guaranteed via camera or DMC.

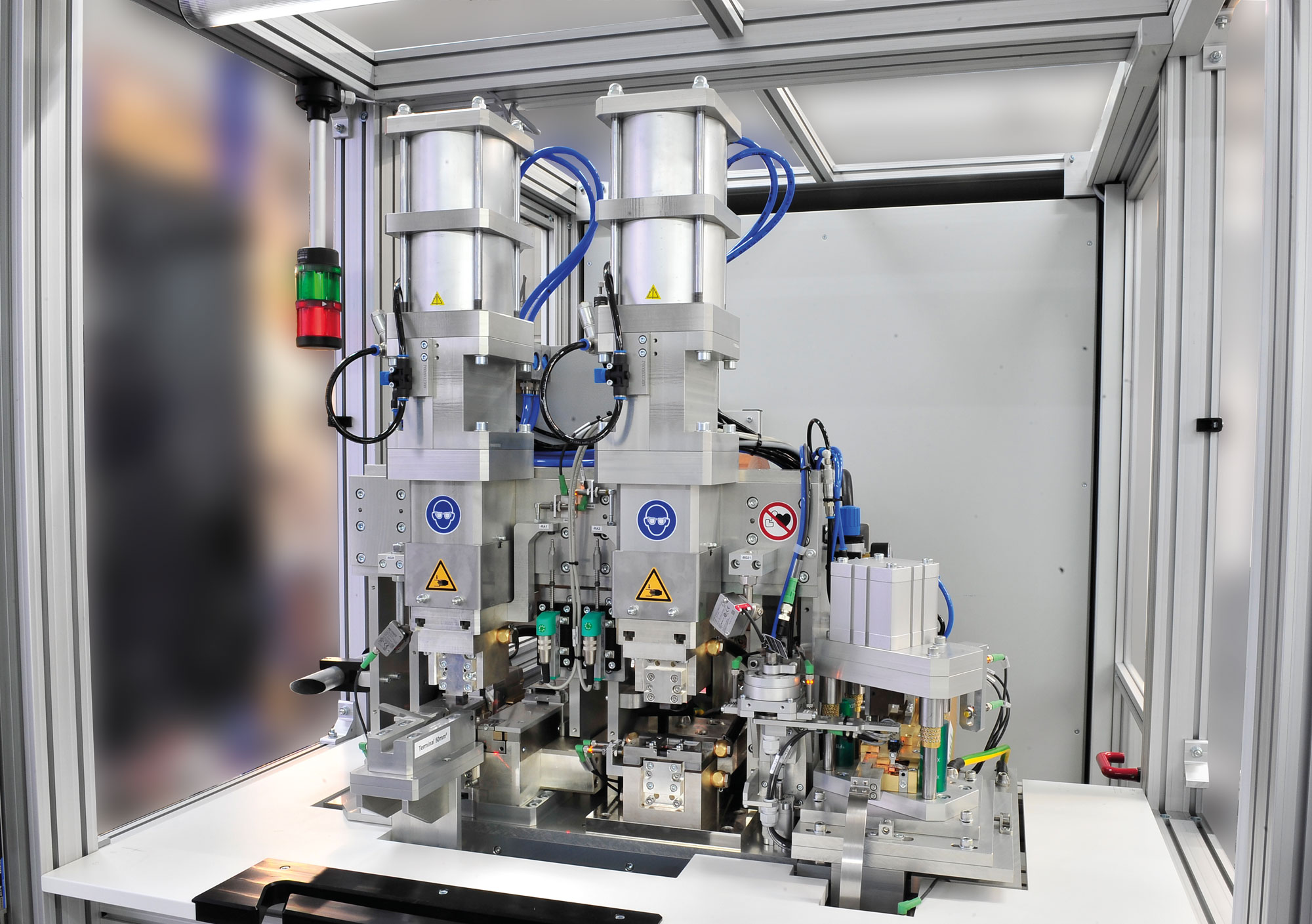

Semi-automatic welding system for stator production

This is a semi-automatic welding system for stator production with a multi-tong system for different welding tasks (hot crimping and welding under braze). Full traceability is guaranteed via camera or DMC. The system can also be connected to STRUNK MES or your specific MES software.

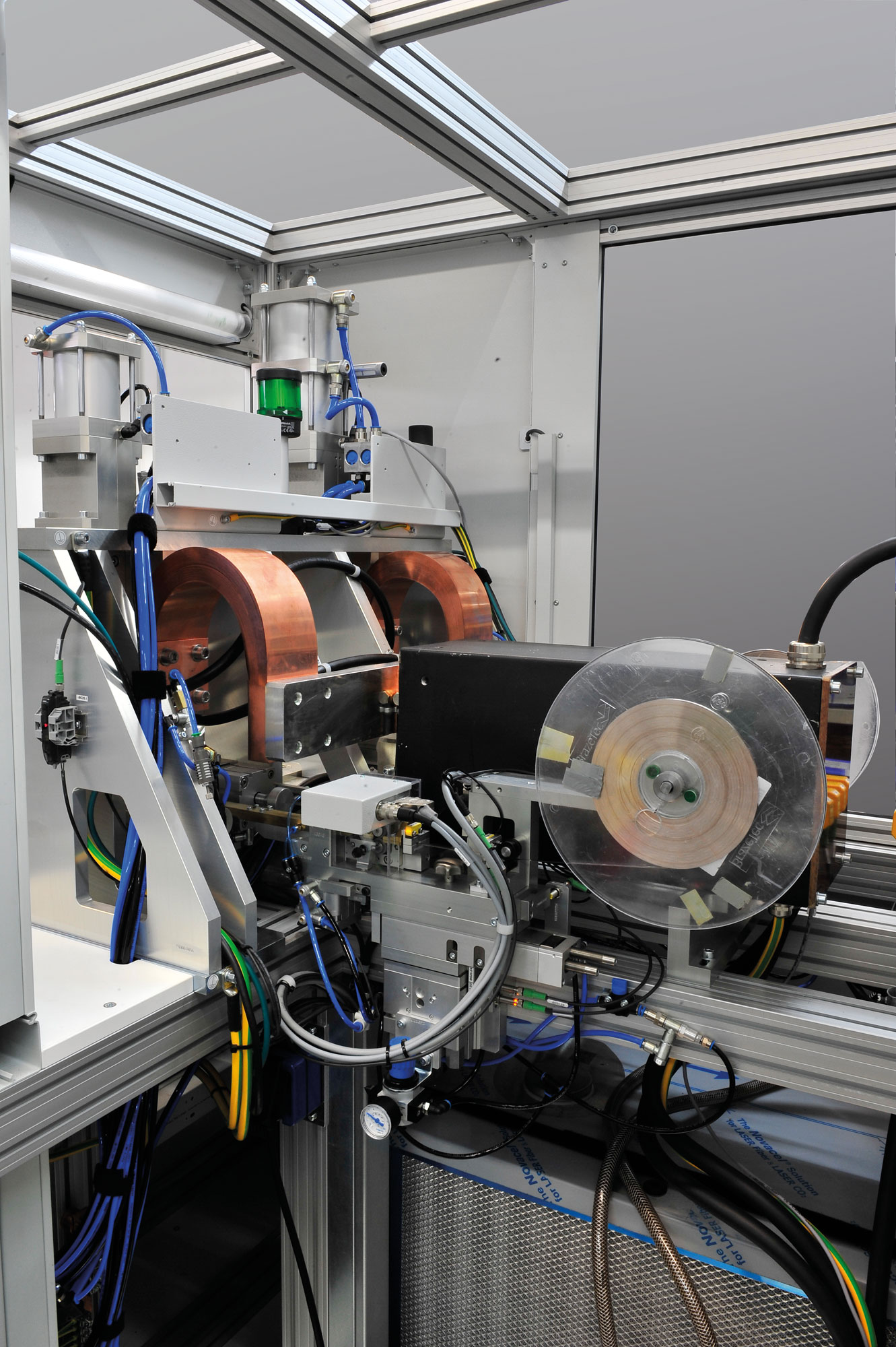

Double-head compacting system for the production of various cross-sections under braze

This customized semi-automatic machine was designed specifically for compacting different cross-sections under braze for subsequent welding onto busbar systems. Production takes place sequentially using the ONE PIECE FLOW process with a subsequent automatic welding process. Compacting under braze allows for welding in confined spaces and at several welding points. The system also offers full traceability via camera or DMC.

Semi-automatic double-head transfer for HV connectors

This flexible semi-automatic welding cell with transfer is suitable for compacting under braze and welding the compacted cable onto an HV connector. By compacting under braze and automatically transferring the compacted wire, the most precise dimensions and reproducibility are achieved. A changeover to another HV connector can be carried out quickly by simply replacing the welding nest. The gripper systems have NOK cutters and full traceability is guaranteed via camera or DMC. Additionally, this welding cell can be connected to STRUNK MES or your specific MES software. It also has an optionally selectable contact part feeder.

Fully automatic system in turntable design for busbar connections under braze with assembly robot

This customized system is designed as a fully automatic machine for welding connections between power distributors (busbars) and connectors. The components are handled and positioned by ceiling-mounted robots. Full traceability is guaranteed for this system by means of a camera or DMC. The system can also be connected to STRUNK MES or your specific MES software.

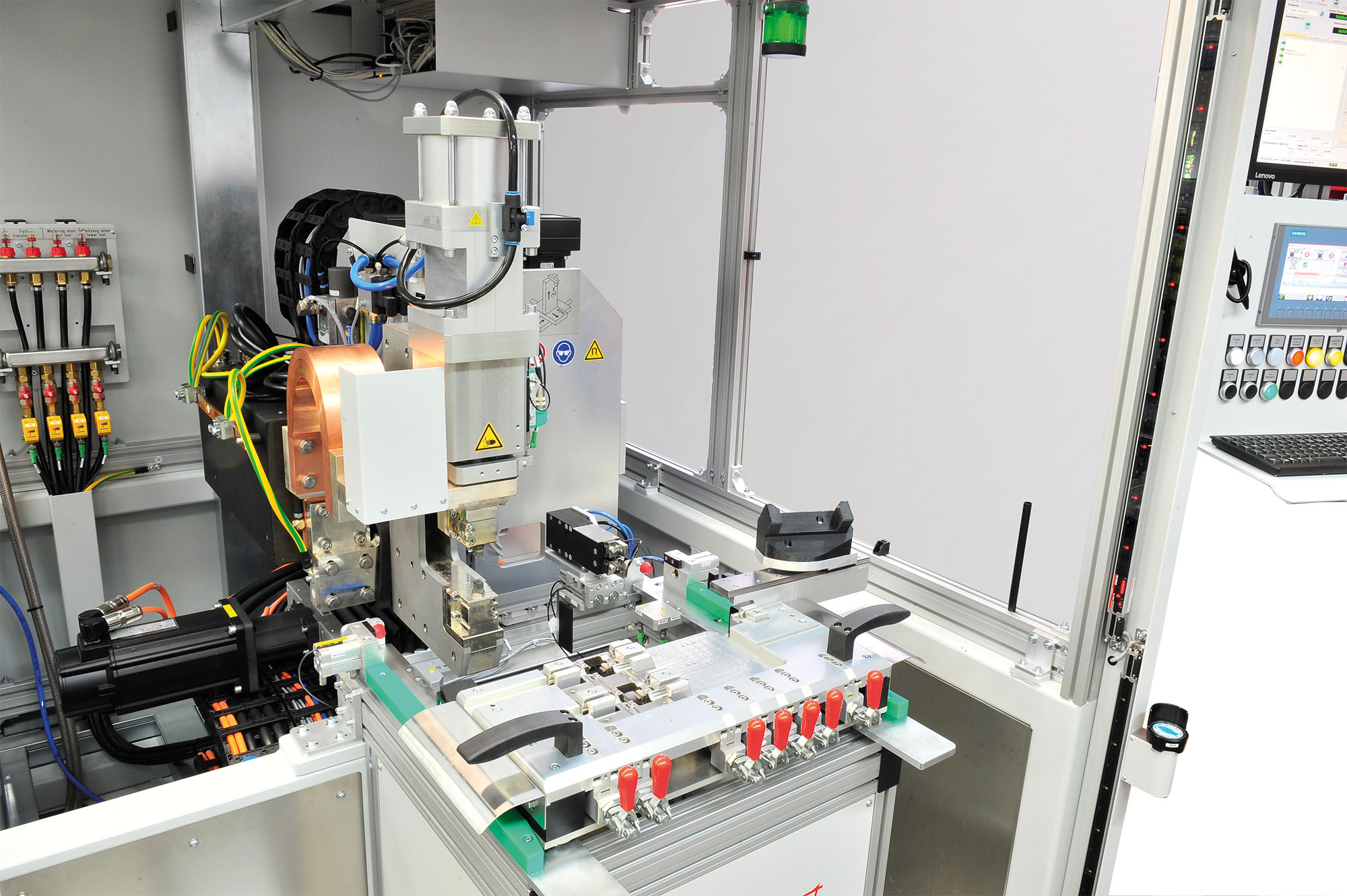

Automatic machine for welding cables with lengths from 25 to 120 mm onto busbars

This is an automatic welding system for connecting HV cables to busbars, with a tool carrier system for complete cable sets. When the coded tool carrier is fed in, the sequential welding process for the complete cable set is started.

Fully automatic machine for welding phase connections and star points on stators

This system is designed for upright stators on tool carrier systems.It features a STRUNK HUBFIX unit with servo drives in the z and rotary axes. Therefore, this four-axis machine can therefore reach and process all positions on a pallet.